Expansion lock Eefde

In Eefde, just north of Zutphen, a second lock chamber has been under construction since the beginning of 2018, which will function as a connection between the Twente Canal and the IJssel and which will eventually function completely energy neutral. TTTBV supplied various RGP frames and RGB frames from MCT Brattberg for this new lock chamber. The new CCM Casting Module was also used during the pouring of the concrete.

The expansion at Sluis Eefde had already been prepared for several years by Rijkswaterstaat. This was considered necessary, since the waiting time at the current lock is more than 30 minutes, making it difficult to estimate the travel time over the Twente Canal. The original lock is also relatively small and shallow. The steady growth of transport by water requires infrastructural investments, whereby bottlenecks in the network of waterways are removed as much as possible.

The second lock, which was built right next to the current lock, is a Dutch first: a lock door that tilts up and down, a so-called segment door. This lock gate is easier to maintain than traditional lock gates and can also still be closed in the event of a calamity, when strong flowing water flows into the lock.

The Lock to Twente (L2T) construction consortium, consisting of Mobilis TBI and CroonWolter&Dros, received responsibility for the complete construction of the new lock from Rijkswaterstaat.

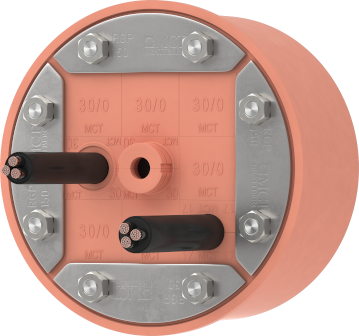

Casting Module CCM

MCT Brattberg cable transits were used to seal the cables, which are necessary for the various control installations in the second lock chamber. When the enormous amounts of concrete, about 8,000 m3, were poured, the new CCM Casting Module was used to create round openings in the concrete. At the Eefde lock, the CCM150 was used to provide the walls with 150 mm large, round openings, which are immediately watertight. As soon as one of the relevant holes is needed to lead cables through, the round deflection valve in the middle of the CCM150 must be removed with a hammer, after which the desired cables can be fed through with the help of an MCT Brattberg RGP150 window and sealed watertight.