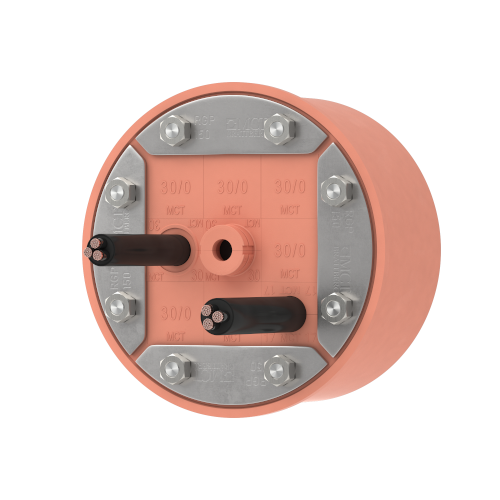

RGP implementation

The RGP is available in a number of sizes as standard. The Ronde RGP can be installed directly in a concrete wall if a suitable hole has been drilled first. A tolerance of 0 – +2mm normally applies to the hole size in the wall. A matching steel jacket, also known as a sleeve, is also available for each RGP size, in which the RGP can be placed. Various sleeve types are available, both with and without a flange and suitable for welding in as well as for surface mounting. In the latter case, the flange is provided with screw holes. The jacket (Sleeve) with flange and screw holes is also available in an open version, for placement around cables or pipes already installed.

Properties

- A60 certified by Lloyds Register and DNV

- EN-1366 tested against fire penetration (integrity 120 min)

- Certified up to a pressure of 1.8 bar (except RGP 300)

- Tested to 4.5 bar (RGP 300: 4 bar)

- Resistant to gas, explosion, water, dust, vermin, etc.

- Available in galvanized steel or stainless steel

- No additional parts or specific work (such as welding) are required for assembly

- Sleeves available in (stainless) steel and aluminum, with and without flange

Directly in concrete or steel conduit

One of the biggest advantages of an RGP penetration is the fact that when used in concrete walls, they can be placed directly in the wall . No sleeve or frame is therefore required for this: the RGP can be placed cold in the round opening in the concrete wall. A precondition for this is, of course, that the drilled hole has the correct size for the relevant round RGP penetration. A tolerance of 0-+2mm applies as standard for this hole size.

For use in a steel wall, it is necessary to place the RGP in a steel sleeve. A round pipe section can also be used to weld into the wall, if it is ensured that the pipe has the correct size and is perfectly round in shape.

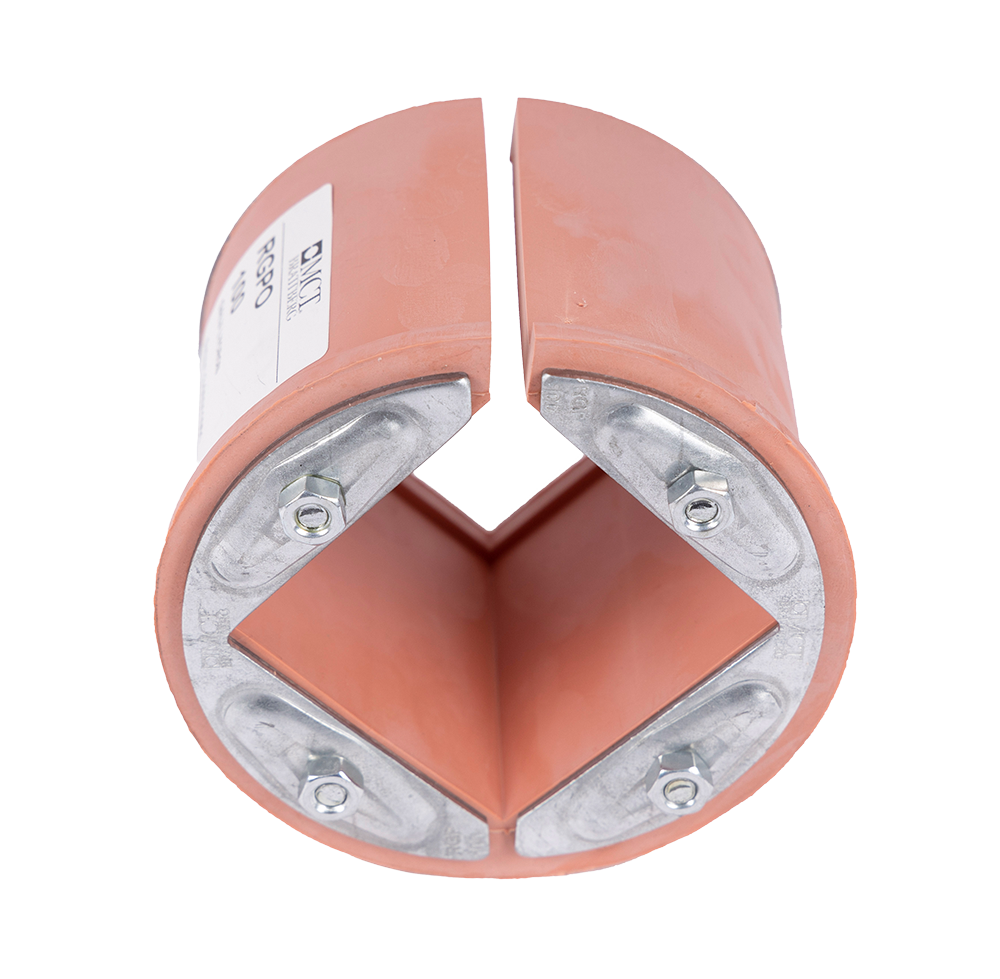

Install afterwards

RGP transits are open in the longitudinal direction, making them suitable as standard for use in projects where the cables have already been drawn and must later be sealed watertight. To do this, the RGP can simply be bent outwards slightly, after which it is slid over the cables until all cables are on the inside of the RGP. Only then should the RGP be fixed in (or on) the wall, after which the passage opening on the inside is closed with cable blocks. The RGP is then made pressure-tight by tightening the bolts around alternately.

Dimensions RGP

The RGP transit is available in 7 standard sizes. These sizes correspond to the most common drill size holes. The RGP100 stands for diameter, and therefore for a hole of 100mm, the RGP150 for a diameter/hole of 150mm. The actual space you have to run cables through is the inner size. Below are the internal dimensions of the various RGPs side by side.