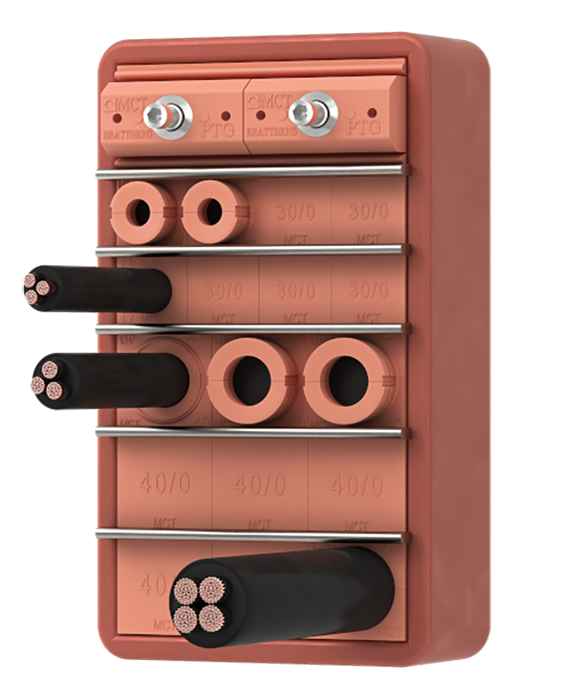

RGS transits

RGS frames and all variations thereof are frames to be welded into metal walls, ceilings or bulkheads. The different types of RGS each have their own application, which is explained below. The RGS frames are available in a large number of sizes and can often also be supplied from stock .

Types of RGS:

- RGS – The standard frame type for marine applications.

- RGSC – Frame with rounded corners, which reduces the risk of cracking in the ship’s hull.

- RGSF – Flanged frame, withstands high pressure in bulkheads and deck.

- RGSK – An extra deep frame, intended for use on outside decks.

- RGSR – Intended for locations subject to extreme loads.

- RGSO – RGS frame with removable end

- RGSbtb – A double frame, which is packed on both sides with filler blocks

RGS frames and all variations thereof are frames to be welded into metal walls, ceilings or bulkheads. The standard RGS windows have (nicely rounded) right angles and, like all RGS frames are made of 10mm thick steel, standard E36.

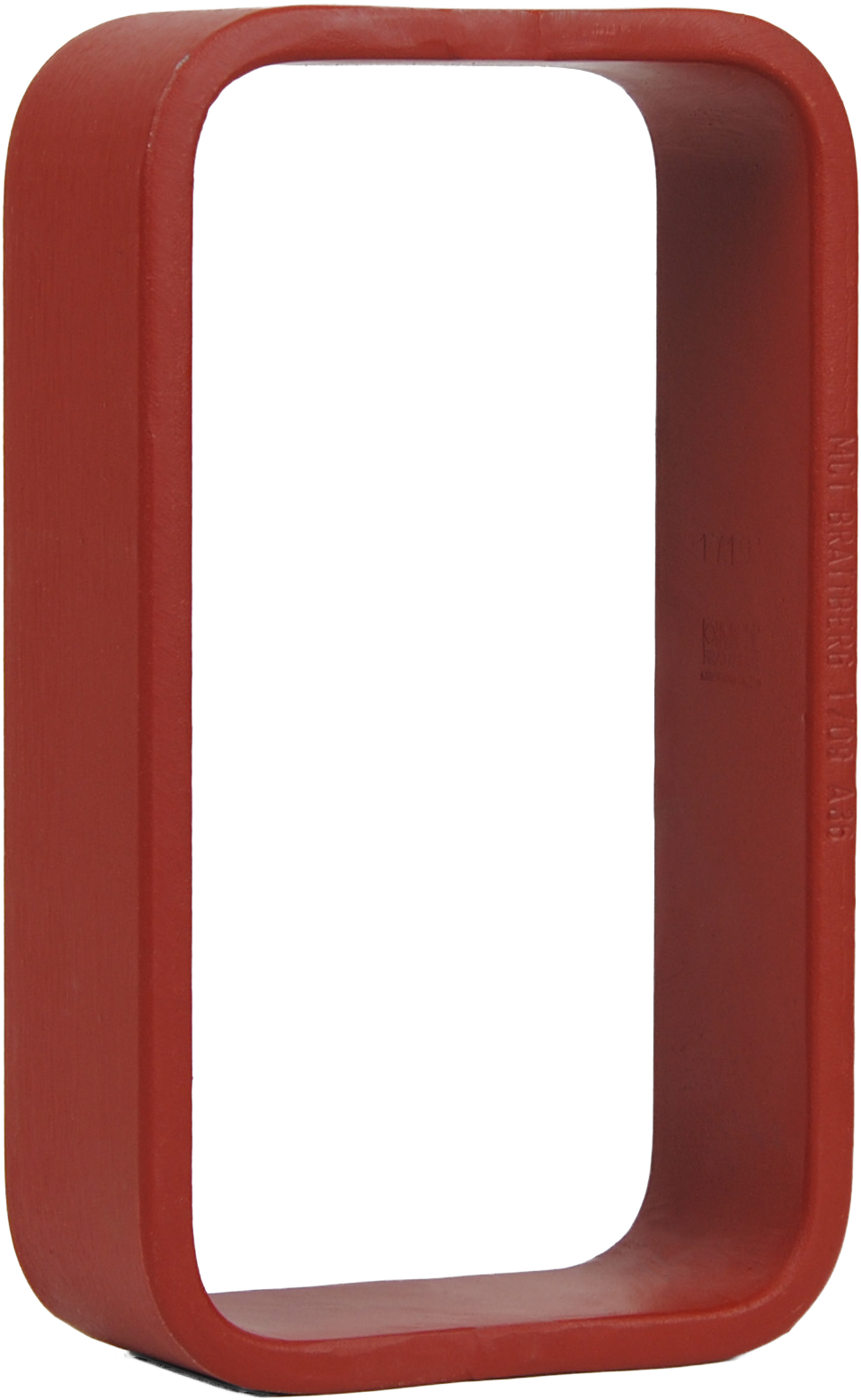

RGSC frames and all variations thereof are frames to be welded into metal walls, ceilings or bulkheads. In contrast to the standard RGS windows, the RGSC windows (C for Corner) are provided with a bent corner. The standard radius of the corners in the RGSC windows is 30mm. The RGSC windows are intended to be easier to weld into a wall, thereby preventing cracking. The rounded corners of the RGSC windows can also withstand slightly greater forces from the wall or floor.

RGSF is a standard RGS window with a flange. This allows the RGSF to be welded into a slightly less precisely cut hole, which must be larger than the grommet itself. The RGSF is available in standard heights 2, 4, 6 and 8 and has the same dimensions as the RGS, with the exception of the flange width: 60mm wide and 10mm thick (on all sides). The RGSF is also available as a multiple frame.

If a penetration is to be placed in a location where the cables have already been routed, an RGSFO or RGSFBO can be used. The RGSO has a removable top, which is attached to the other window parts with bolts and nuts.

The RGSFB is similar in shape to the RGSF, but has bolt holes. The RGSFB is always supplied complete with stainless steel bolts, nuts and a watertight gasket. The RGSFB is intended for situations where welding is prohibited (such as in certain offshore environments) or where welding poses too great a risk to the integrity of the wall or floor in question.

RGSK is a recessed, standard RGS window, provided with machined grooves for the placement of stayplates and the end seal. The material is 10mm thick at the ends and 12mm at the sides. The RGSK is available in heights 2, 4, 6 and 8.

RGSK windows are recommended if the transit blocks are to be mounted above standing water, for example on a wet deck, or in a thicker wall. The window is 120mm deep (versus 60mm for the RGS) and has the same standard width on the inside of 120mm.

RGSR is used in bulkheads that can withstand extreme loads. The additional parts with rounded corners stabilize the window in relation to the wall and reduce the risk of cracking in the respective wall. The radius of the ends is 70mm. The internal part of the RGSR is completely comparable to the RGS and available in heights 2, 4, 6 and 8.

RGSRs can also be supplied as multiple frames, with both horizontal and vertical combinations possible.

The RGSFBO is an RGSFB that has one side that can be opened. This allows the RGSFBO to be opened and placed around existing and routed cables. After this, the loose element must be reconnected to the rest of the lead-through frame, by means of the supplied bolts, nuts and a gasket. Like the RGSFB, the RGSFBO must be mounted on a steel wall or floor using bolts, nuts and a gasket. For the RGSFBO it is therefore not necessary to weld. However, bolt holes must be made in the wall or floor, so that the flange of the RGSFBO can be positioned appropriately over the through-hole by means of the supplied bolts and nuts.

The RGSbtb is used, among other things, to create completely gas-tight spaces, where each penetration can be tested separately before the building or installation is taken into use. The RGSbtb, which is specially classified for this purpose, is also chosen when there is a risk of jet-fires. This is the case, for example, when there is a risk that pressurized fuel lines will be damaged and the fuel will spray out of the resulting opening.

The RGSbtb offers the end user the option to test each individual penetration for pressure tightness after installation. To this end, the intermediate chamber, between the two rows of blocks, is filled with water via a valve and put under pressure. In that case, in addition to the filling valve, each penetration is provided with a pressure gauge, so that the pressure in the inner chamber can be measured.

In stock

MCT Brattberg transit products are used daily. From experience we know how important it is to maintain sufficient stocks, so that we can always meet the high logistical requirements set by the market as much as possible. A large part of the MCT Brattberg range is kept in large stock in our warehouse in the Netherlands.

In the webshop you can see the current stocks from our warehouse. Normally we can deliver the products in stock within 24 hours, if ordered before 3 p.m.