High pressure cable transits

High pressure transits are designed for situations where the standard MCT cable transits (5 bar) no longer meet the requirements, in very high pressure conditions such as in offshore or submarines. MCT Brattberg has a number of different high pressure transits, all of which are custom made. The RGPM and RGPH are transits for multiple cables up to a continuous pressure of 15 bar. When you have to feed a cable under extreme conditions, the LSJ and PHP transits are the right choice. Both tested to a pressure of 90 bar.

In addition to the penetrations, MCT also has an Encapsulation option, which seals sensors and connectors for very high pressure (50 bar) conditions.

RGPM implementation

RGPM pressure penetrations are used under, or in the vicinity of, water. It is approved for a continuous pressure of up to 15 bar. The implementation of the RGPM is based on customer-specific data. The RGPM is available with a diameter of 50-500mm and for every possible configuration in cables. The outer diameter is matched to the inner diameter of the pipe or hole in which the RGPM is to be placed. The penetration is normally made of Nitrile rubber, but depending on the application, other materials are also used. Steel parts are hot-dip galvanized or stainless steel, or any other material that meets the application requirements. The penetrations can be supplied with rubber seals pre-adjusted to the cable or pipe diameter.

The RGPM can be designed as a blind seal to create a temporary seal, which provides space for cables and pipes to pass through at a later date. In situations where there may be pressure differences, a self-closing version of the RGPM can be used; the penetration then automatically adapts to the varying pressure.

Properties

- Suitable for pressures up to 15 bar

- Customer-specific development

- Individual inspection and test per transit, prior to delivery

Download brochures

RGPH high pressure transit

The RGPH high pressure transit has been developed as an extremely compact cable transit for sealing under high pressure. It has been developed for use in, for example, the legs of drilling platforms or between compartments of submarines. The custom multi-cable and conduit high pressure seal can be designed to seal 1-36 cables with a diameter of 4-110mm depending on the pressure.

The RGPH system is available in six sizes based on the seal diameter (mm), RGPH-50, 70, 100, 125, 150 and 200. Each RGPH is specially developed for the requested application.

Properties

- Customer-specific development

- Tested up to a pressure of 100 bar and certified up to 40 bar

- DNV approved

LSJ Joint

The LSJ (Longitudinal Sealing Joint) is used to route an electrical cable through a tank/pipe between two pressure-tight sections and to form a pressure-tight unit with the tank/pipe (RGPH seal) against incoming pressurized media through the cable if it is damaged or cut in the pressure-tight parts.

The test pressure is 90 bar.

There are two types of LSJ available:

LVT Longitudinal sealed (the basic type of LSJ).

When a cable is cut on the high pressure side (HP) LSJ stops incoming water and protects the low pressure side (LP) from overpressure and water.

LVTT Longitudinal and Cross Sealed

If one or more of the cables on the HP side are damaged or cut, those cables will be blocked, while the undamaged cables are still intact.

Both types (LVT and LVTT) can be supplied with built-in protection against EMP (Electromagnetic Pulse from Lighting and Nuclear Explosion).

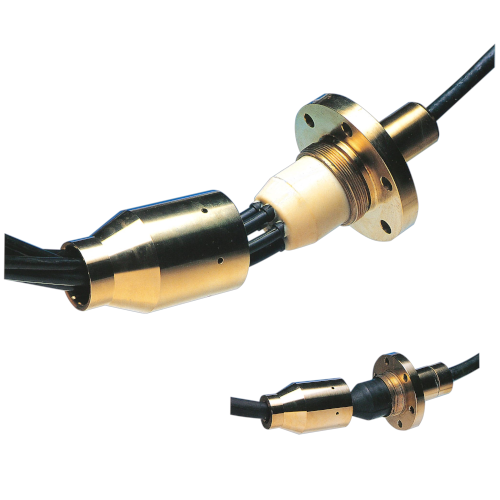

PHP penetration

The PHP (Pressure Hull Penetrator) is used to route an electrical cable through a pressure hull and to form a pressure tight unit with the pressure hull against overpressure media through the cable if the cable is damaged or cut on the high pressure side.

The test pressure is 90 bar.

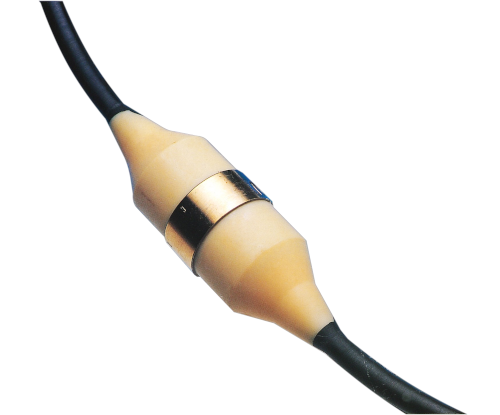

Encapsulation

The encapsulation of inductive sensors and connectors is used to ensure a watertight seal. It is a custom designed product that is tested and inspected to specifications.

The encapsulation of sensors and connectors is used to ensure a watertight seal. Application dimensions and types of sensors and connectors are determined by the customer. The sensors and connectors are currently used in various types of submarines.